Eyes on invisibility. Sanezoo's unique product is making its mark in the USA.

Walking on the surface does not imply superficiality. Certainly not in the case of Sanezoo. The company is automating surface quality control and robot guidance using machine vision and artificial intelligence, and is making inroads into foreign markets including the United States.

Official Forbes Magazine article

can be found here:

Twenty-one, eye candy! Not just any eye, not just any bank. Sanezoo gives eyes to robots, and they notice what human eyesight has no chance of seeing, which intrigued the Venture Club investment fund so much that it gave the Brno company a generous gift for Christmas last year.

As part of its twenty-first project - and with Venture Club CEO Petr Šedivý's comment that Sanezoo, targeting the global market, is an ideal opportunity for investors - it increased its investment in the company to CZK 44.44 million.

"We have had smaller investors, so we have raised about CZK 140 million in the six years of the company's existence," reveals Luboš Brzobohatý, founder and CEO of Sanezoo. "It is a reasonable assumption that the money will return to the investors several times over. We are not a company that can't find paying customers at the beginning, because we have to generate interest first."

It would be almost strange if Sanezoo's product didn't generate interest. Because it can do what has been an unsolvable problem until now: qualitatively evaluate products whose surface has been a problem for robots because it has been painted, glossy or milled, which creates confusing reflections on the surface.

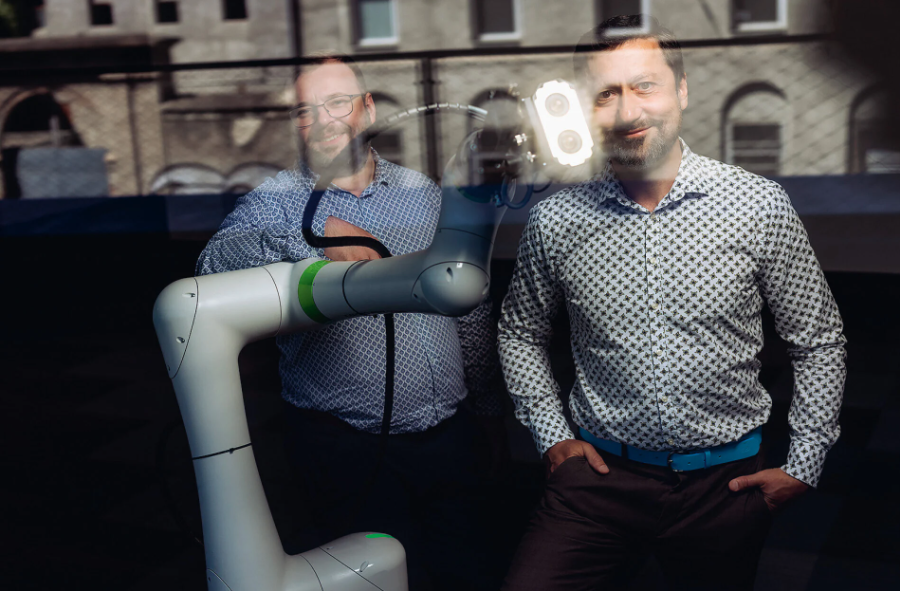

It is not confusing for the technology that two Brno engineers, two Lubošs, came up with, because besides Luboš Brzobohatý, Luboš Lorenc also founded the company and is its shareholder. Robotic eyes that overcome invisibility are already used by large concerns such as Škoda Auto, Bosch, ZF, Magna or Denso.

Apart from the Czech Republic, these eyes help customers in the UK, Japan, Poland, Hungary, Mexico and the USA. In the United States - where it has won its first three customers - the Brno-based company is building a branch, as the potential of the market there is huge and the production segment is not nearly as stagnant as in Europe.

At the time of writing, Brzobohatý resided in Cincinnati, a city located in the middle of the American industrial belt, so it may be a very good strategic location to set up a branch office. Sanezoo only started offering its product commercially the year before last, but as it quickly caught on, a plan for a 160 million crown turnover this year seems realistic.

This would be an eightfold year-on-year increase. This may be the start of a great ride, the end of which is now hard to see. Especially when one doesn't have robot eyes.

Surface quality control and robot guidance using machine vision and artificial intelligence. The formulation of what's on offer from Brno doesn't sound sexy at first hearing, but appearances are deceiving - it's extremely attractive to customers. Robotic vision first and foremost eliminates the human imperfections that breed mistakes.

These errors are all the more likely because if quality control is carried out by employees on the production line in, say, an automobile factory - and automobile manufacturers or suppliers of components to automobile manufacturers are logically Sanezoo's most frequent customers - their concentration on monotonous and several-hour-long work must almost inevitably be subject to fluctuations.

Of course: that this is exactly the job for robots, so that employees can do something more meaningful, is now clearer than the dawn of a cloudless summer day, with which a Moravian company would not figuratively or literally discover America. "But we are solving problems that manufacturing companies have not yet been able to solve," says Brzobohatý.

We solve problems that manufacturing companies have not yet been able to solve.

"This means checking harder-to-scan - typically glossy - surfaces. Camera systems have problems with differently reflected light and various artefacts that they see as aberrations, even if these are only visual differences, not functional defects. So often this is a false identification of a defect, but our system, called Unity, can correctly evaluate even difficult-to-distinguish variations such as a scratch or indentation, and thus distinguish defective pieces from good ones.“

Under Špilberk, a special design of luminaires has been created for different materials and different types of products. The luminaires are composed of a large number of independently controlled sections, and their gradual activation imitates a person who, for example, rotates a shiny object in the light in order to find the angle of view at which he can detect the defect..

Several images of the part with different illumination parameters are taken in rapid succession, analyzed and then evaluated. Unity combines hardware, software and artificial intelligence, using its own neural networks and decision-making algorithm.

The system can work with a robotic arm to inspect parts from one millimetre to several metres, depending on the needs of the specific plant. The data that the device works with does not leave the factory, which increases the system's cyber security.

And Unity is not the only product line offered. There's also Grasp, the result of the realization that machine vision and robotic manipulation are related and used together in manufacturing. Brzobohatý and Lorence's company originally focused only on camera systems, but the founders gradually realized how useful it was to combine this technology with robotic.

A system for 3D picking of parts from boxes and for loading them into the machine or line was developed. While the part is being handled, an automatic visual quality check can be performed simultaneously in conjunction with Unity; Grasp looks a bit like a robust bird leaning intently over an open crate, taking the desired object in its beak.

It then moves the gripped component to the "nest" or destination. This technology also saves time and staff, which are in short supply due to the low attractiveness of the work, leading to the unpleasant necessity of rejecting orders.

While the robot sets up the parts with unerring persistence, Brzobohatý, the founder of the company, tells us about another way of setting up: "We pride ourselves on making sure that both our systems are deployed easily so that the client does not waste time with integration services, thus saving weeks of work.“

It saves weeks of work, it saves employees, and it most likely saves reputational risk and significant amounts of money spent in fines for shenanigans that the industrial company would have delivered to the contracted partner, but thanks to Sanezoo's early detection, it does not deliver.

Therefore, Brzobohatý's claim of a very fast return on investment in systems that start at roughly thirty thousand dollars and end at ten times that price is plausible.

Have they hit a golden business vein in Brno? Anyway, Sanezoo got a gold medal from Brno. It won it at last year's International Engineering Fair in the category of Innovation in Automation Technology and Industry 4.0.

"In addition to the automotive sector, we supply manufacturers of electronics, medical technology, and we are useful to the aerospace industry. When I talk to representatives of other companies, I hear about the problems they have in getting a foothold.“

We are able to compete with companies with billions of dollars in turnover.

"Our know-how is so unique that it is interesting even for large corporations, and we are able to compete even with companies with billion-dollar turnovers," says Luboš Brzobohatý in a voice whose tone is close to a dry statement, with no trace of pretentious boastfulness.

Expectation and hope are mixed into this tone when there is talk of expansion across the Atlantic. There is also sincerity in the tone: 'Unfortunately, in the Czech environment, envy plays a role, in the sense that if the technology we offer is handled by a 'no name' company, they can do it themselves without help, and sometimes we see a tendency to undermine us, to throw sticks under our feet.“

"In the States, the mentality is set purely on wanting to make money, save labor and therefore money, give the most value to the end customer and get paid for it. That's also why we are very attracted to further business development there.“

On the American surface, Sanezoo seems to be breathing the air for an exciting adventure. The advantage is that he's an expert on surfaces.