GRASP

Precise Picking & Feeding

Precise Picking & Feeding

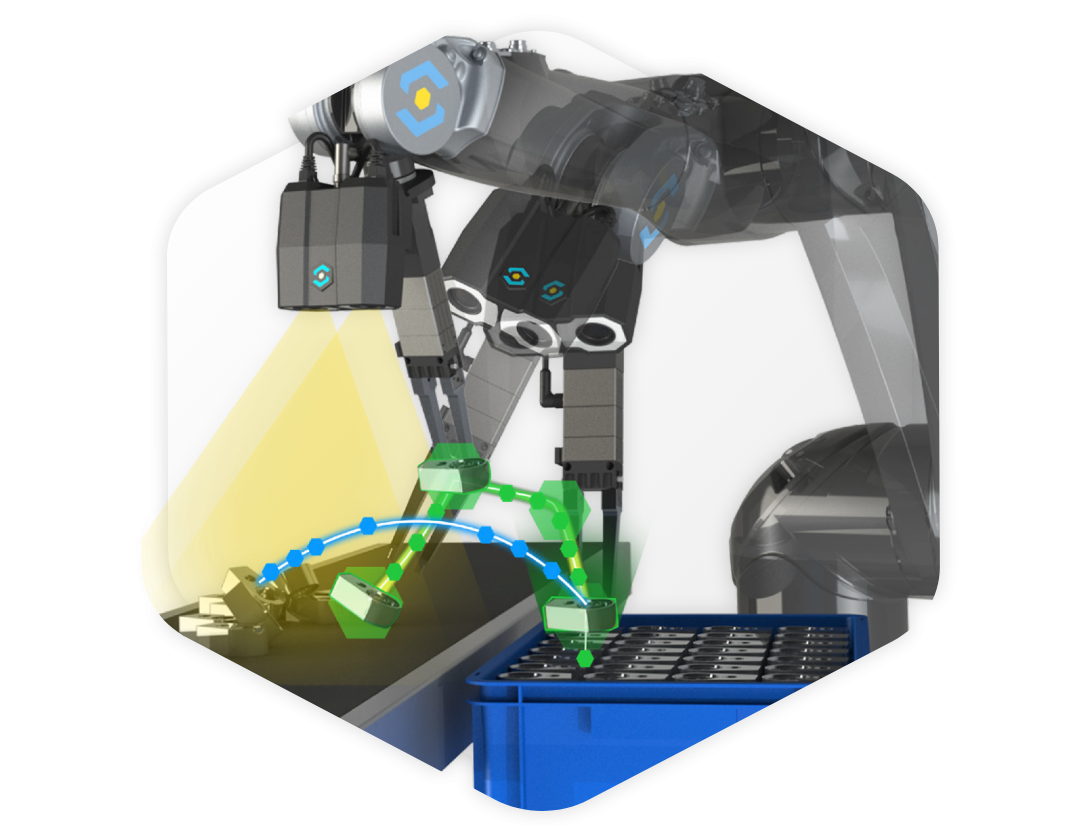

Grasp is a revolutionary system designed for perfect part handling using robotic guidance in 3D space. This innovative system acquires 3D scenes, identifies objects and their positions, and optimizes collision-free trajectories for efficient lifting and handling of parts.

Flexibility and speed of implementation:Grasp can be deployed and integrated into operations in a matter of hours, providing a fast and flexible solution for flexible production needs.

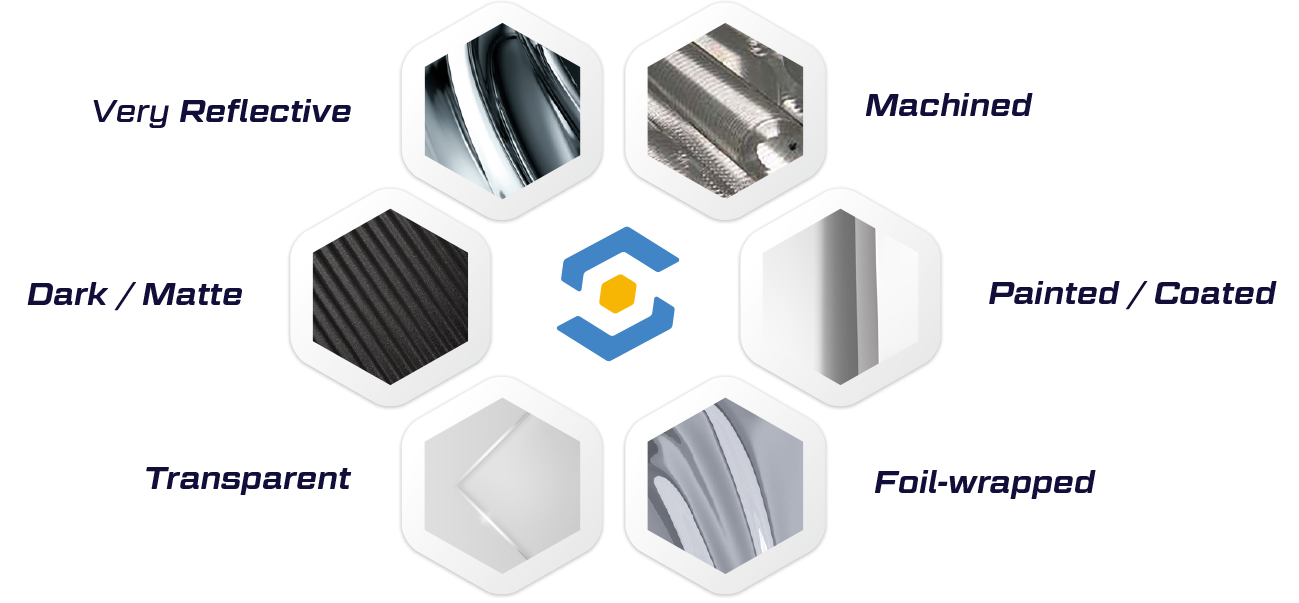

Optimization in different environments: it can handle a variety of materials and surfaces, including glossy, matte, and complex surfaces, for example in the automotive, electronics, or medical industries.

Grasp can calculate and optimize full collision-free trajectories for lifting parts, allowing the robot to make smooth and precise movements.

The Grasp system handles parts handling even in the event of unexpected obstacles, minimizing process interruptions

SANEZOO Grasp is designed to be manufacturer-independent, allowing it to be used with different types of robots

-creates routes from start to finish on the fly

-can guide from the final position directly inside the box

-knows grip position oriented placement

Universal for containers of all sizes From small crates to net pallets Handles even very small parts in large containers

The SANEZOO system can accurately collect parts from the top and bottom of very deep containers. The image remains perfectly sharp due to the constant working distance.

From total darkness to direct sunlight Unaffected by variations in lighting conditions, it guarantees stability day and night, even in extreme light or darkness.

SANEZOO GRASP works like a pair of eyes. You don't need projectors or lasers. Ideal for metal, machined, glossy or matte parts

and scenes with multiple materials in the field of view.

-any size from 5 mm up

-geometric or complex shapes

Please contact us and we will be happy to go through the solution options with you in detail. And if you want to test a specific sample from your production, you can send it to us for analysis and see the results on the spot.

Trusted by Industry Giants: Our Esteemed Partners and Clients

Please contact us and we will be happy to go through the solution options with you in detail. And if you want to test a specific sample from your production, you can send it to us for analysis and see the results on the spot.